- Home

- About Us

Gallery

We have provided professional products and solutions for metal packaging, automobile manufacturing, new energy vehicles, household appliances, wind power generation, railway construction and other fields...

- Products

ETP

Electrolytic Tin Plate (ETP/TP), with good corrosion resistance, strength and hardness, is good in forming and welding. The tin layer is non-toxic and tasteless, can prevent iron from being dissolved into the packaged object, and the surface is bright, and the printed picture can beautify the product.

TFS

Electrolytic Tin Free Steel (TFS), also known as Electrolytic Chromium Coated Steel (ECCS), is a type of steel that is coated with a thin layer of chromium and chromium oxide through an electrolytic process. This coating provides the steel with excellent corrosion resistance, a superior surface finish, and good paint adhesion properties

TMBP

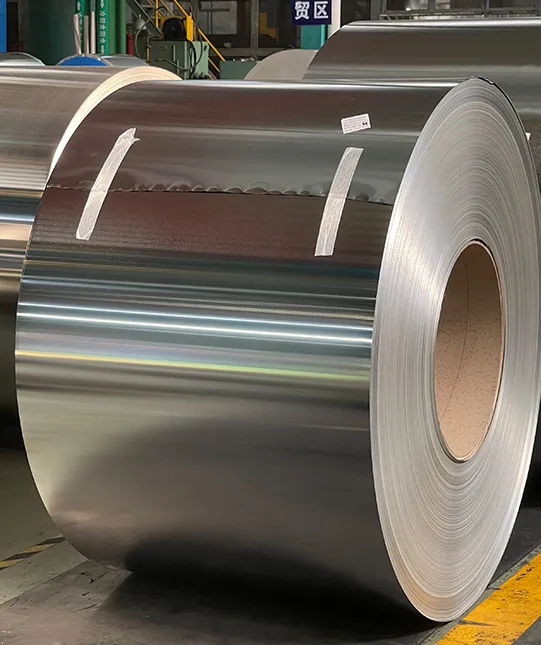

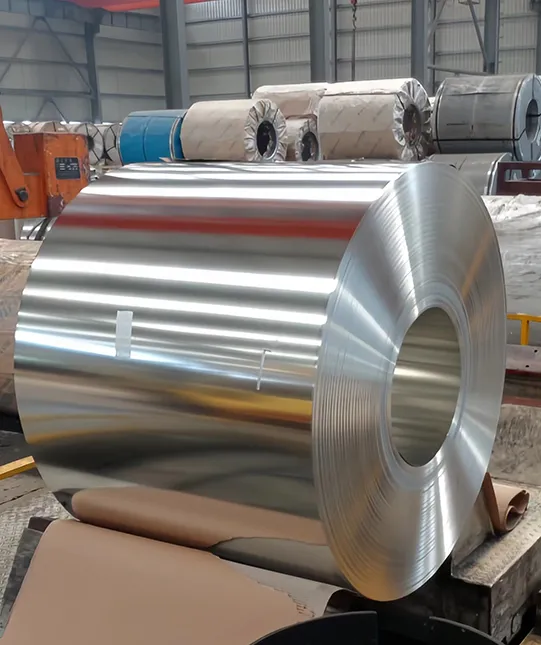

Tin Mill Black Plate (TMBP/BP) is an uncoated, thin, and cold-rolled steel sheet that serves as a substrate for tinplate and tin-free steel production. It is made from low-carbon steel and is characterized by its smooth surface finish, uniform thickness, and good mechanical properties.

Lacquered & Printed Tinplate

Lacquered & Printed tinplate and Tin-Free Steel sheets are low carbon coated steel or printed with polymer coatings and inks respectively. Those materials are commonly used for metal cans and components, both for food (sanitary) and industrial applications.

Easy Open End

The Canned Food Easy Open End (EOE) made from tinplate is a key component in the packaging industry, particularly for food products. Tinplate, known for its excellent corrosion resistance and formability, ensures that the easy-open end provides a reliable seal to maintain the freshness and safety of the canned contents.

Bottom End

The Bottom End made from tinplate is a crucial component in the canning and packaging industry. Known for its durability, excellent corrosion resistance, and formability, tinplate is the preferred material for producing bottom ends that provide a secure and reliable seal for canned goods.

Peel Off End

The Peel Off End made from tinplate is a specialized lid designed for easy and convenient access to canned products. This type of end is typically composed of a tinplate ring with a thin, peelable aluminum or laminated foil layer that seals the container.

Twist-off Cap

The Twist-Off Cap made from tinplate is a widely used closure for jars and bottles, particularly in the food and beverage industry. This cap is designed to be easily screwed on and off by hand, providing a convenient and reliable seal.

Aerosol Cap

The Aerosol Cap made from tinplate is an essential component of aerosol cans, which are widely used for dispensing products in the form of sprays, foams, or mists. This cap is designed to fit securely over the can’s nozzle, providing protection and ensuring the safety of the product during storage and transport.

- Industry Application

- Sustainability

- Careers

Working at HIGHSEN PACKAGING

Highsen Packaging specializes in tailored metal packaging solutions, designed to meet diverse client needs. We aim to be your trusted partner in the industry by offering high-quality products, excellent service, and long-term collaboration.

Job Opportunities

Highsen Packaging specializes in tailored metal packaging solutions, designed to meet diverse client needs. We aim to be your trusted partner in the industry by offering high-quality products, excellent service, and long-term collaboration.

Q&A

Highsen Packaging specializes in tailored metal packaging solutions, designed to meet diverse client needs. We aim to be your trusted partner in the industry by offering high-quality products, excellent service, and long-term collaboration.

- Media

Download

We have provided professional products and solutions for metal packaging, automobile manufacturing, new energy vehicles, household appliances, wind power generation, railway construction and other fields...

- Contact Us

中文

中文